Researchers 3D print key components for a point-of-care mass spectrometer

The low-cost hardware outperforms state-of-the-art versions and could someday enable an affordable, in-home device for health monitoring.

Mass spectrometry, a technique that can precisely identify the chemical components of a sample, could be used to monitor the health of people who suffer from chronic illnesses. For instance, a mass spectrometer can measure hormone levels in the blood of someone with hypothyroidism.

But mass spectrometers can cost several hundred thousand dollars, so these expensive machines are typically confined to laboratories where blood samples must be sent for testing. This inefficient process can make managing a chronic disease especially challenging.

“Our big vision is to make mass spectrometry local. For someone who has a chronic disease that requires constant monitoring, they could have something the size of a shoebox that they could use to do this test at home. For that to happen, the hardware has to be inexpensive,” says Luis Fernando Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories (MTL).

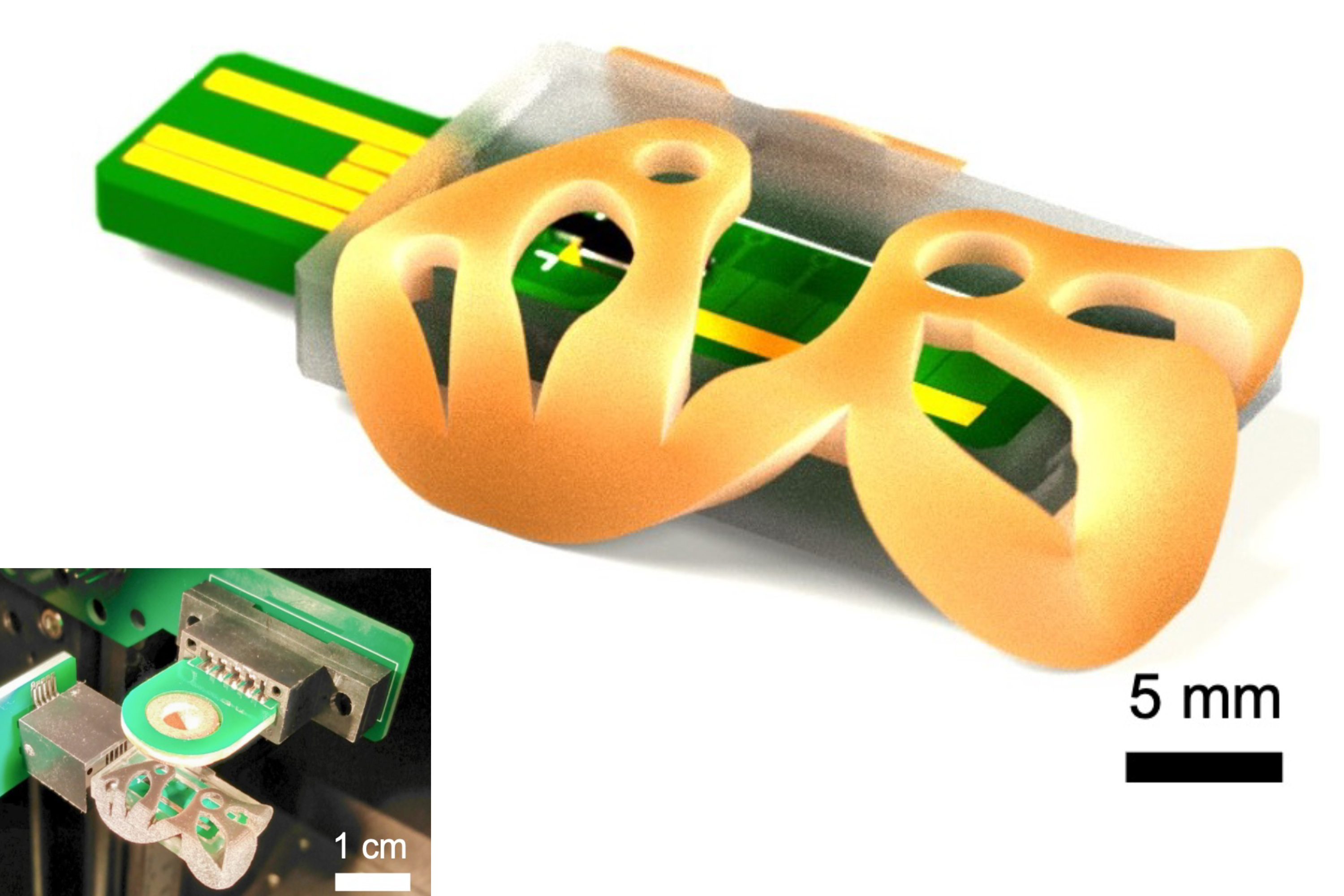

He and his collaborators have taken a big step in that direction by 3D printing a low-cost ionizer — a critical component of all mass spectrometers — that performs twice as well as its state-of-the-art counterparts.

Their device, which is only a few centimeters in size, can be manufactured at scale in batches and then incorporated into a mass spectrometer using efficient, pick-and-place robotic assembly methods. Such mass production would make it cheaper than typical ionizers that often require manual labor, need expensive hardware to interface with the mass spectrometer, or must be built in a semiconductor clean room.

By 3D printing the device instead, the researchers were able to precisely control its shape and utilize special materials that helped boost its performance.

“This is a do-it-yourself approach to making an ionizer, but it is not a contraption held together with duct tape or a poor man’s version of the device. At the end of the day, it works better than devices made using expensive processes and specialized instruments, and anyone can be empowered to make it,” says Velásquez-García, senior author of a paper on the ionizer.

He wrote the paper with lead author Alex Kachkine, a mechanical engineering graduate student. The research is published in the Journal of the American Association for Mass Spectrometry.

Low-cost hardware

Mass spectrometers identify the contents of a sample by sorting charged particles, called ions, based on their mass-to-charge ratio. Since molecules in blood don’t have an electric charge, an ionizer is used to give them a charge before they are analyzed.

Most liquid ionizers do this using electrospray, which involves applying a high voltage to a liquid sample and then firing a thin jet of charged particles into the mass spectrometer. The more ionized particles in the spray, the more accurate the measurements will be.

The MIT researchers used 3D printing, along with some clever optimizations, to produce a low-cost electrospray emitter that outperformed state-of-the-art mass spectrometry ionizer versions.

They fabricated the emitter from metal using binder jetting, a 3D printing process in which a blanket of powdered material is showered with a polymer-based glue squirted through tiny nozzles to build an object layer by layer. The finished object is heated in an oven to evaporate the glue and then consolidate the object from a bed of powder that surrounds it.

“The process sounds complicated, but it is one of the original 3D printing methods, and it is highly precise and very effective,” Velásquez-García says.

Then, the printed emitters undergo an electropolishing step that sharpens it. Finally, each device is coated in zinc oxide nanowires which give the emitter a level of porosity that enables it to effectively filter and transport liquids.

Thinking outside the box

One possible problem that impacts electrospray emitters is the evaporation that can occur to the liquid sample during operation. The solvent might vaporize and clog the emitter, so engineers typically design emitters to limit evaporation.

Through modeling confirmed by experiments, the MIT team realized they could use evaporation to their advantage. They designed the emitters as externally-fed solid cones with a specific angle that leverages evaporation to strategically restrict the flow of liquid. In this way, the sample spray contains a higher ratio of charge-carrying molecules.

“We saw that evaporation can actually be a design knob that can help you optimize the performance,” he says.

They also rethought the counter-electrode that applies voltage to the sample. The team optimized its size and shape, using the same binder jetting method, so the electrode prevents arcing. Arcing, which occurs when electrical current jumps a gap between two electrodes, can damage electrodes or cause overheating.

Because their electrode is not prone to arcing, they can safely increase the applied voltage, which results in more ionized molecules and better performance.

They also created a low-cost, printed circuit board with built-in digital microfluidics, which the emitter is soldered to. The addition of digital microfluidics enables the ionizer to efficiently transport droplets of liquid.

Taken together, these optimizations enabled an electrospray emitter that could operate at a voltage 24 percent higher than state-of-the-art versions. This higher voltage enabled their device to more than double the signal-to-noise ratio.

In addition, their batch processing technique could be implemented at scale, which would significantly lower the cost of each emitter and go a long way toward making a point-of-care mass spectrometer an affordable reality.

“Going back to Guttenberg, once people had the ability to print their own things, the world changed completely. In a sense, this could be more of the same. We can give people the power to create the hardware they need in their daily lives,” he says.

Moving forward, the team wants to create a prototype that combines their ionizer with a 3D-printed mass filter they previously developed. The ionizer and mass filter are the key components of the device. They are also working to perfect 3D-printed vacuum pumps, which remain a major hurdle to printing an entire compact mass spectrometer.

“Miniaturization through advanced technology is slowly but surely transforming mass spectrometry, reducing manufacturing cost and increasing the range of applications. This work on fabricating electrospray sources by 3D printing also enhances signal strength, increasing sensitivity and signal-to-noise ratio and potentially opening the way to more widespread use in clinical diagnosis,” says Richard Syms, professor of microsystems technology in the Department of Electrical and Electronic Engineering at Imperial College London, who was not involved with this research.

This work was supported by Empiriko Corporation.

What's Your Reaction?